| Contact Us |

Director:Cao Yunqing

M.T:(0)13906121025

Tel: 86-519-88903560 88902690

Fax:86-519-8903560

E-mail£ºcyqhx@sina.com

Add:Chajiawan,Jiaoxi Town,

Wujin,Changzhou,Jiangsu |

|

Current Position£ºHome - Products Current Position£ºHome - Products | |

|

|

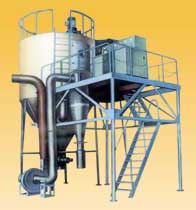

| LPG Series High-Speed Centrifugal Spary Drying Machine |

| LPG Series High-Speed Centrifugal Spary Drying Machine |

Work Elements Work Elements The air exchange to be hot air through the heat exchanger, then enter the hot fan dispatcher at the top of the drying room. The feed liquor be sended to the centrifugal atomizer at the same time. The atomizing feed liquor contact with the hot air and make the moisture be vaporized quickly. The finished product be discharged through the bottom of the drier and the rolling separator. The exhaust gas be discharged at the same time.

Main Specialty

A. Fast drying. The surface area will be increased for it's atomizing condition. The 65%~98% moisture will be vaporized in 5~15 seconds. It's fit the heat sensitivity especially.

B. The graininess is well-proportioned, it improve the product's purity.

C. Operate simple and control easy.

D. Predigest the production run. Avoid the dust pollute during product.

|

|

- air filter

- heater

- hot wind divider

- drying room

- filter

- pump

- nozzle

- cyclone type divider

- fan facilities

- feed liquid slot

|

Technical Parameters

|

|

LPG |

|

5 |

25 |

50 |

100 |

150 |

200-2000 |

|

Entry temperature¡£C |

140-350 autocontrol |

|

Exit temperature¡£C |

-80-90 |

|

Max moisture evaporation capacity

kg/h |

5 |

25 |

50 |

100 |

150 |

200-2000 |

|

Atomizing spray heat drive model |

compressed air drive |

machine drive |

|

rotate speed(r.p.m) |

25000 |

18000 |

18000 |

18000 |

15000 |

8000-15000 |

|

spray disc's diameter

(mm) |

50 |

120 |

120 |

120 |

150 |

180-340 |

|

Heat source |

electrity |

electrity |

electrity & steam fuel gas |

electrity & steam |

electrity & steam fuel gas |

be solved by the customer |

|

Electric Heating Max Power KW |

8 |

31.5 |

60 |

81 |

99 |

|

|

Form measure length*width*height(m) |

1.8x0.93x2.2 |

3x2.7x4.26 |

3.7x3.2x5.1 |

4.6x4.2x7 |

5.5x4.5x6 |

be confirmed with the physical circumstance |

|

Dry dust reclaim rate% |

¡Ý95 |

¡Ý95 |

¡Ý95 |

¡Ý95 |

¡Ý95 |

¡Ý95 |

|

Note: the wet evaporation capacity be affected by the raw material and the hot fan entry's temperature. |

Applying scope Applying scope

-

*Chemical industry

-

sodium fluoride, alkalescent dye, alkalescent intermediate,catalyzer,amino acid,silica pigment

-

*Plastic resin

-

AB, ABS latex, bakelite, formaldehyde resin, polyethylene, PVC

-

*Foodstuff industry

-

whole milk powder, cocoa milk powder, soybean milk powder, egg white and so on.

-

Food and plant

-

oat, coffee, instant tea, sauce, protein, bean, hydrolyzate and so on

-

Glucide

-

corn steep liquor, corn flour, glucose, pectin, malt dust and so on

-

Chinawarealumina, ceramic tile, magnesia, pencil stone and so on

|

°²×°³ß´çͼ£º

|

Order Notice

- Aqueous feet name and characteristic: water content, viscosity, surface tension, PH

- Finished product's water content, graininess and the allowabel temperature

- output everyday

- Useable power source: the available steam pressure; quantity of electric charge; the available coal, oil and steam.

- Control request: whether the entry and the exit temperature should be autocontrol

- Dust reclame request: whether need the dust filter with cloth bag. the request for environmental protection.

- Any other specific request

|

|

size |

A |

B |

C |

D |

E1 |

E2 |

F |

G |

H |

I |

|

LPG-25 |

1290 |

3410 |

4260 |

1800 |

1200 |

1200 |

1000 |

1700 |

1300 |

1550 |

|

LPG-50 |

1730 |

4245 |

4645 |

2133 |

1640 |

1640 |

1250 |

1750 |

1800 |

1600 |

|

LPG-100 |

2500 |

5300 |

6000 |

2560 |

2100 |

2100 |

1750 |

1930 |

2600 |

1780 |

|

LPG-150 |

2800 |

6000 |

6700 |

2860 |

2180 |

2180 |

1970 |

2080 |

3050 |

1960 |

|

LPG-200 |

2800 |

6600 |

7300 |

3200 |

2300 |

2300 |

2210 |

225 |

3050 |

2100 |

|

LPG-300 |

2800 |

8000 |

8700 |

3700 |

2800 |

2800 |

2520 |

2400 |

3050 |

2250 | | |

|

|

|